|

|

|

|

|

|

|

|

|

| Daito Co,Ltd. |

| Head Office・Tokyo Branch |

Showa Build.3F,12-8 Nihonbashitomizawa-cyo,

Cyuo-ku,Tokyo 103-0006

TEL 03-3669-4511 |

|

| Osaka Branch |

5-11 Shinden-nakamachi,

Daito-shi,Osaka 574-0056

TEL 072-806-7661 |

|

|

|

|

|

|

|

|

|

|

| Molybdenum disulfide is the most popular solid lubricant which is glossy grayish-colored powder with very soft, low coefficient of friction, strong load-bearing, high allowable temperature limit and easy-to-adhere-to metal properties. |

Coefficient of friction ・・・・・・・・・ 0.03

Pressure tightness ・・・・・・・・・・・・・ 2900MPa(about 29 ton per 11cm2)

Heat resistance ・・・・・・・・・・・・ -180℃ 〜 +450℃ |

| Powder of 0.4 micron on average in size with these properties attaches to convexo-concave of the metal surface and alleviates shock of metal on metal. |

|

|

|

|

|

Viewed under a microscope, the metal surface is not level.

Particulate molybdenum disulfide attaches to convexo-concave of cylinder, piston and piston ring surfaces, alleviates the shock of metal on metal (or metal contact), and dramatically lowers the friction with coefficient of friction of μ=0.03.

Attaching to convexo-concave, it raises compression, enhances explosive power and powers up.

Furthermore, with its high allowable temperature limit, strong load-bearing and easy-to-adhere-to-metal properties, it produces an effect and continues its effect even under harsh conditions such as high rotation area where pistons and piston rings are pressed to cylinders strongly

Molybdenum disulfide film allows the engine to start smoothly at the time of staring a car.

Thus, “HI POWER JET” is a product to make the best use of molybdenum disulfide properties. |

|

|

|

|

|

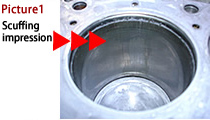

Although pistons at a speed of about 3,000 rotations a minute go and return along cylinders (Figure 1), those at a speed of 8,000 rotations a minute go and return pressing on cylinders due to centrifugal force of crankshaft movement and piston weight (Figure 2).

This causes scuffing impression in cylinders as shown in (Picture 1).

Scuffing impression means wear. This gives various impacts such as oil gassing off from worn cylinders, compression down (power down), etc (Figure 3).

The best oil couldn’t prevent scuffing impression in cylinders. As a countermeasure, competition cars process molybdenum disulfide to lower the coefficient of friction on the skirt of pistons (Picture 2).

In this way, “HI POWER JET (Molybdenum disulfide powder)” contributes to alleviate friction as a countermeasure of scuffing and recover compression after wear. |

|

|

|

|

|

|

|

|

|

|

|

|